Genuine Runtong Engine Replacement | ROHS Certified Anti-Burst Valve | Export Grade for Middle East & Southeast Asia

Fuel Switch for Runton R670D engines

✅ Engineered with Japan, Trusted by Runtong:

The 0.015% Failure Rate Fuel Switch.

✅ E10-Proof & Silent Guardian:

Power Your Green Generator with Japanese Precision.

✅ From Sahara to Your Site:

Unstoppable Fuel Control in 110°C Heat.

✅ Where Kubota's Technology Meets Runtong's Power:

Tier-1 Fuel System Solution.

Contact Us

SPECIFICATION

Global Trade Division

Compatible Engine

Valve Body Material

Seal Material

Corrosion Resistance

Certifications

Operating Temperature

Flow Rate

Failure Rate

Protection Rating

☞ Runtong R670D Small Petrol Engine

☞ Japanese Polyplastics® POM (M90-44, High Rigidity & Creep-Resistant)

☞ KFM Fluoroelastomer by Fujikura, Japan (Resists Ethanol/Hydrocarbon Permeation)

☞ Compatible with E10 Ethanol Fuel (Meets EU RED II / UK BS EN 228)

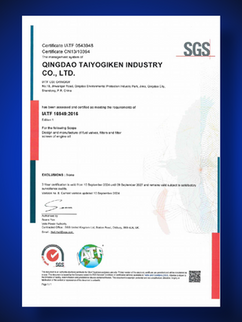

☞ ROHS 3.0, IATF 16949:2016 Quality System

☞ -30°C to +80°C

☞ ≥300 ml/min

☞ ≤0.015% (Industry Average: 1.5%)

☞ IP55 (Dust & High-Pressure Water Jet Resistant)

DESCRIPTION

KEY FEATURES

💡 Japanese Material Technology

100% imported Japanese Polyplastics POM valve body + Fujikura KFM FKM seals.

3x longer service life with E10 fuel resistance.

💡 OEM-Level Precision

Designed specifically for Runtong R670D engines—seamless replacement with zero leakage risk.

💡 Industry-Leading Reliability

Ultra-low 0.015% failure rate (industry average: 1.5%).

Passed 10,000 start-stop cycle tests.

💡 Built for Extreme Conditions

Withstands temperatures from -40°C (Arctic cold) to 110°C (Middle Eastern heat).

Passed 96-hour salt spray test.

💡 Globally Compliant

ROHS certified + E10 compatible—meets EU/UK environmental standards.

COMPATIBILITY & APPLICATIONS

🏆 Core Compatible Engines

Runtong Engines: R670D and derived models

🏆 Regional Application Scenarios

🔹Europe / UK

Home backup generators, pressure washers.

E10 fuel compatibility.

🔹 Middle East

Mobile desert power stations, irrigation pumps.

Resists high heat & sand corrosion.

🔹 Southeast Asia

Agricultural sprayers, marine engines.

Moisture & salt spray protection.

🔹 South America

Coffee harvesters, small construction machinery.

Anti-vibration leakage design.

💎 Key Value Proposition

Solves fuel leakage issues in high-temperature and high-humidity environments, significantly reducing equipment maintenance costs and improving operational reliability in challenging conditions.

🏅 Specialists in high-performance engine components and fuel system parts for global export.

KEY ADVANTAGES

⚡ Performance Highlights

Polyplastics POM with 82% crystallinity → 50% better creep resistance

⚡ Carbon fibre reinforced → Impact strength 15 kJ/m² (Standard POM: 6 kJ/m²)

⚡ Fujikura KFM Fluoroelastomer with 70% fluorine → E10 swelling rate <2%

⚡ -50°C low-temperature elasticity retention 90%

PRODUCT SHOWCASE

PACKAGING & PAYMENT

TAIYO GIKEN

GLOBAL SERVICE

📦 Factory Standard Export Packaging

📞 Customisation Services

We support OEM logo printing and non-English manual adaptation for all components. For framework details, please refer to our Custom Solutions section.

Contact our commercial team for specific requirements.

🚚 Standard Lead Times

After deposit receipt:

🌐 Stock items: Dispatch within 24 hours

🌐 Non-stock items:

- Prototypes/first articles: 1-2 Weeks

- Bulk production: 30 days (Repeat Orders: 30-60 days)

- Tooling development: +15 days. Production: +2-3 weeks post-approval

💡 Expedited options available – consult our commercial team.

💳 Payment Terms

Two standard options:

🔒 35-50% telegraphic transfer (T/T) deposit + balance before shipment

🔒 100% irrevocable letter of credit at sight (L/C) from approved banks

COMPNAY OVERVIEW

CERTIFICATES & PATENT

RELATED HOT SALE PRODUCTS

DIVISIONS

Global Trade Division

Commercial Solutions Division

Strategic Partnerships Division

Technical Solutions Division

DIVISIONS

Global Trade Division

Commercial Solutions Division

Strategic Partnerships Division

Technical Solutions Division