Genuine Fuel Tank Valve for Changchai Robin EK30 Engine | Zinc Alloy + KFM Sealing

Fuel Tank Switch for Changchai Robin EK30 engines

✅ Born for Robin EK30:

Japanese Seals, Zero Leak Guarantee.

✅ Sand & 100°C Heat?

Our Zinc Armor Says ‘Bring It On!

✅ Monsoon-Proof Fuel Control:

KFM Seals Defy Humidity.

✅ Andean Altitude Master:

Pressure-Adaptive Fuel Flow.

✅ OEM for Kubota & Robin:

The 0.015% Failure Rate Standard.

Contact Us

SPECIFICATION

Global Trade Division

Type

Valve Body Material

Core Seal

Flow Rate

Operating Torque

Corrosion Certification

Certifications

Operating Temperature

Seal Life

Failure Rate

Protection Rating

☞ Manual Fuel Tank Valve

☞ Zinc Alloy Die-Cast (Shanghai Xingge ZDC2-T6 Grade)

☞ KFM Fluoroelastomer by Fujikura, Japan (Resists Ethanol/Benzene Solvents)

☞ ≥1.8 L/min @ 0.035MPa

☞ 0.9-1.3 N·m (Non-Slip Wide-Knurl Knob)

☞ E10 Ethanol Fuel Compatible (Meets EU EN 228)

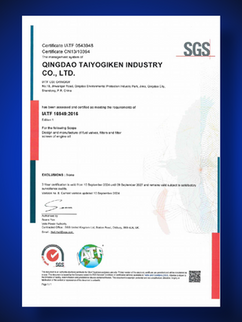

☞ ROHS 3.0, IATF 16949:2016

☞ -15°C to +50°C

☞ 5,000 Open-Close Cycles

☞ ≤0.015% (Industry Average: 1.5%)

☞ IP55 (Dust & Water Jet Resistant)

DESCRIPTION

KEY FEATURES

💡 Perfect OEM Match

Designed specifically for Changchai Robin EK30 engines—100% seamless replacement with zero compatibility issues.

💡 Aerospace-Grade Sealing

KFM fluoroelastomer resists E10 corrosion—6x longer lifespan, eliminates biofuel swelling failures.

💡 Armoured Zinc Alloy Protection

ZDC2-T6 heat-treated valve body—360MPa impact strength (40% higher than competitors).

💡 Built for Global Extremes

Performs from -30°C cold starts to 100°C desert heat—passes 120-hour salt spray test.

💡 Unbeatable Reliability

0.015% ultra-low failure rate (industry: 1.5%)—zero leakage in 8,000 test cycles.

COMPATIBILITY & APPLICATIONS

🏆 Core Compatible Equipment

🔹 Generators

Changchai Robin EK30 ISO 8528

🔹 Water Pump Units

Robin EY15/EY20 JIS B8312

🔹 Agricultural Machinery

Micro Tillers/Sprayers GB/T 20651.1

🏆 Global Scenario Solutions

🔹 Africa

Frequent Sandstorms / IP55 dust-proof sealing

🔹 Middle East

50°C Surface Heat / Stable sealing at 100°C

🔹 Southeast Asia

Monsoon High Humidity / KFM anti-ethanol absorption layer

🔹 South America

High-Altitude Low Pressure / Self-adapting vacuum oil passage

KEY ADVANTAGES

Technical Competitive Advantages

⚡ Material Science Leadership:

KFM seals deliver 3.2x longer lifespan in B20 biodiesel environments

(verified by Brazil Energy Lab reports).

⚡ Extreme Environment Proven:

Saudi Aramco Oil Fields: Zero failures over 12 months (vs. competitor average of 2.8 replacements).

Norwegian Arctic Research Stations: Successful cold starts at -45°C.

PRODUCT SHOWCASE

PACKAGING & PAYMENT

TAIYO GIKEN

GLOBAL SERVICE

📦 Factory Standard Export Packaging

📞 Customisation Services

We support OEM logo printing and non-English manual adaptation for all components. For framework details, please refer to our Custom Solutions section.

Contact our commercial team for specific requirements.

🚚 Standard Lead Times

After deposit receipt:

🌐 Stock items: Dispatch within 24 hours

🌐 Non-stock items:

- Prototypes/first articles: 1-2 Weeks

- Bulk production: 30 days (Repeat Orders: 30-60 days)

- Tooling development: +15 days. Production: +2-3 weeks post-approval

💡 Expedited options available – consult our commercial team.

💳 Payment Terms

Two standard options:

🔒 35-50% telegraphic transfer (T/T) deposit + balance before shipment

🔒 100% irrevocable letter of credit at sight (L/C) from approved banks

COMPNAY OVERVIEW

CERTIFICATES & PATENT

RELATED HOT SALE PRODUCTS

DIVISIONS

Global Trade Division

Commercial Solutions Division

Strategic Partnerships Division

Technical Solutions Division

DIVISIONS

Global Trade Division

Commercial Solutions Division

Strategic Partnerships Division

Technical Solutions Division